Have you mastered this repair technique for powder dryer machine shaft head wear?

August 23, 2023

Powder dryer machine is a mechanical device that uses heat energy to reduce the moisture content of a material and is used to perform drying operations on objects. The powder drying machine causes the moisture in the material to vaporise and escape through heating in order to obtain a solid material with a specified moisture content. The purpose of drying is for material use or further processing needs.

The enterprise in an equipment inspection found that the dryer shaft head high temperature and accompanied by strange noise, disassembled and found that the shaft head is worn out seriously, the rear shoulder is also worn out. It was too late for offline repair, and it took 15 days to disassemble and repair. At that time, the enterprise contacted a laser cladding unit, which used on-site laser cladding and then on-site machining to repair the dryer shaft head wear. However, through technical analysis, it was found that the roundness could not be guaranteed after on-site machining, and the surface of the car was elliptical, so that the bearings could not be shaped to fit well with the axle head after being installed in place, and it was only a point fit with the line fit, which could not satisfy the long-term operation of the equipment.

Afterwards, the person in charge of the powder dryer equipment of the enterprise learnt about us, and learnt that our technology can not only repair the wear problem of the shaft head of the dryer online, but also the repaired shaft head can reach the original matching surface with the new bearings, and the fastest repair work can be completed in just a few hours. According to the pictures and data of the equipment provided by the enterprise, our company formulated the corresponding repair programme, and the person in charge of the enterprise's equipment established and cooperated with our company immediately after seeing the programme.

In the repair work of dryer shaft head wear, our company adopts carbon nanopolymer material, and pays attention to the following repair points in the repair process:

(1) Check whether the shaft is bent or not;

(2) Confirm that the positioning surface is not worn to ensure the coaxiality after repair;

(3) Measure the size of the shaft head at multiple points after the repair is completed to ensure that the interference meets the bearing assembly tolerance;

(4) Install the bearing first, wait for the temperature of the bearing to drop before installing the bearing housing. Then the powder drying equipment was repaired successfully.

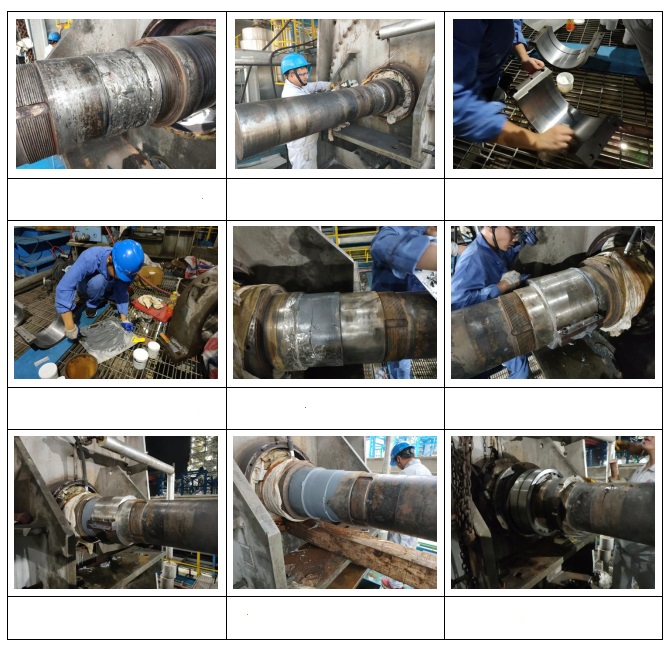

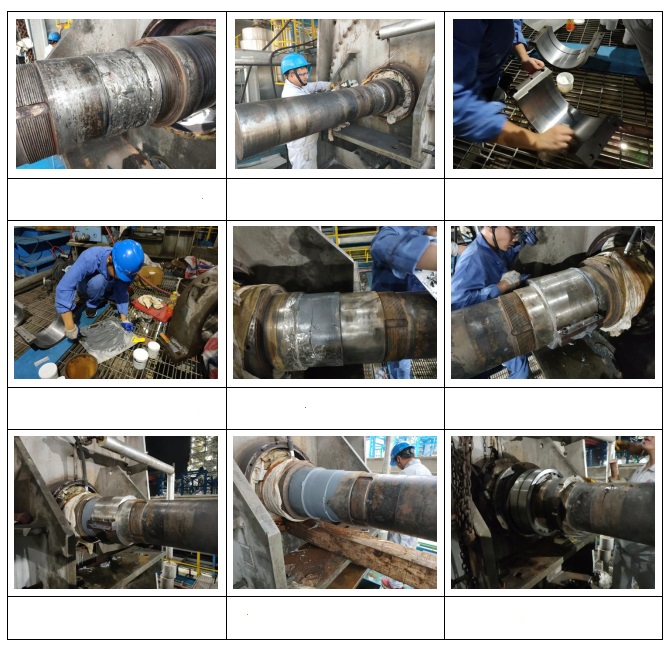

Finally, let's take a look at our engineers to repair the dryer shaft head wear on-site work process.